PRODUCERS

we contribute to the safeguard of our environment by forging connections with producers of alternative fuels that are made without the use of carbon intensive feedstock.

Steps to ensure our cooking oil quality

We validate the weight of oils

Once the drivers arrive from their routes, the product is unloaded and registered at the plant, being weighed on a certified scale.

Quality Control

We verify the quality. As soon as the product is weighed, a sample is taken for laboratory analysis

Reception of use cooking oils

we receive the oil in our treatment centres.

Heating tanks

If the oil arrives solidified, we transfer it to tanks equipped with serpentines to decompact the oil before it undergoes filtration

Filtering tanks

The oil is poured to remove impurities such as food residues or particles remaining in the oil

Storage tanks.

After filtration, the oil is sent to the storage tanks until reaching quantities suitable for export

Standards for our used cooking oils

Max Moisture average

1%

Max Impurities average

1%

Max Acidity average

5%

We are accredited under international standards

Shipping logistics process

Packing type for transportation:

FLEXIBAG

Packing type for transportation:

ISOTANK

Capacity

22 TONS

Capacity

22 TONS

Length

20 FEETS

Lenght

20 FEETS

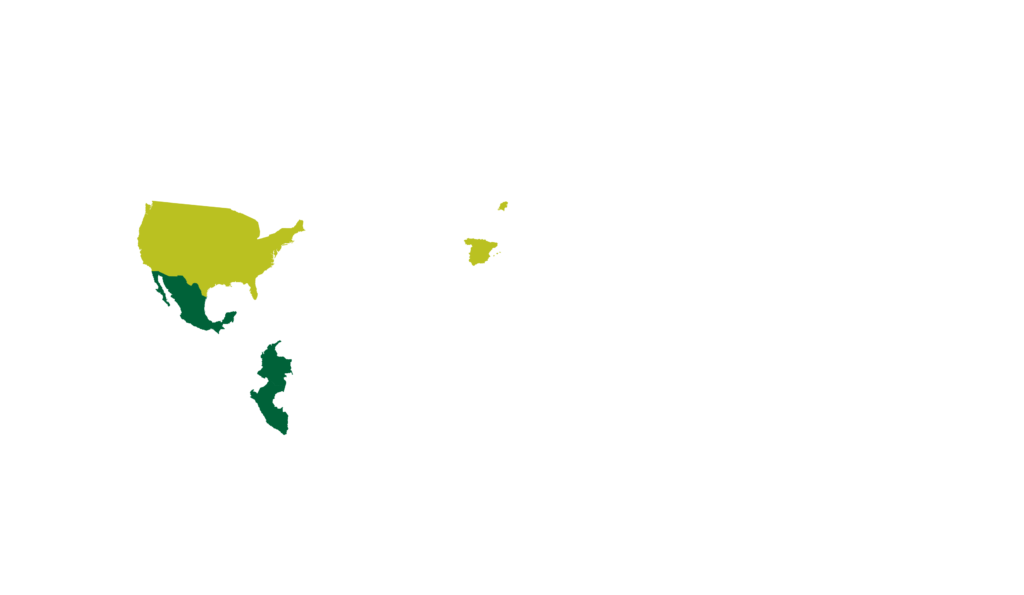

We have a privileged location in Colombia with access to both oceans: the Pacific via the Panama Canal and the Atlantic from the Caribbean Coast. This allows us to provide effective delivery of our products in various ports in USA or Europe.

We deliver used oil to the United States in the Gulf of Mexico area: Houston, New Orleans, Florida, and we aim to reach California. In Europe, our primary delivery points are Rotterdam in the Netherlands and Spain. We adapt to each client’s needs regarding shipment types and contract terms.

Where we are

Suppliers

Producers

Global Presence

Tizona BioEnergy has a network of commercial subsidiaries as well as recycling plants spread across Europe and Latin America.

1%